CAS NO. 25587-80-8

Molecular formula:(C11H23NO2)x

Performance and application

It is made by high temperature reaction of dimeric acid and polyamine.Soluble in general organic solvents, its heating melting viscosity and heating temperature has a great relationship. It has the characteristics of low viscosity, good flow performance, good toughness and high bond strength.

Performance Characteristics

- It has good low temperature solubility and soluble fusibility

- It has high thermal stability.

- It has strong flexibility.

Usage

- Hot melt adhesive for electronic and electrical shrinkable materials.

- shoe material, clothing, leather and other hot glue.

- hot melt adhesive, etc

Specifications

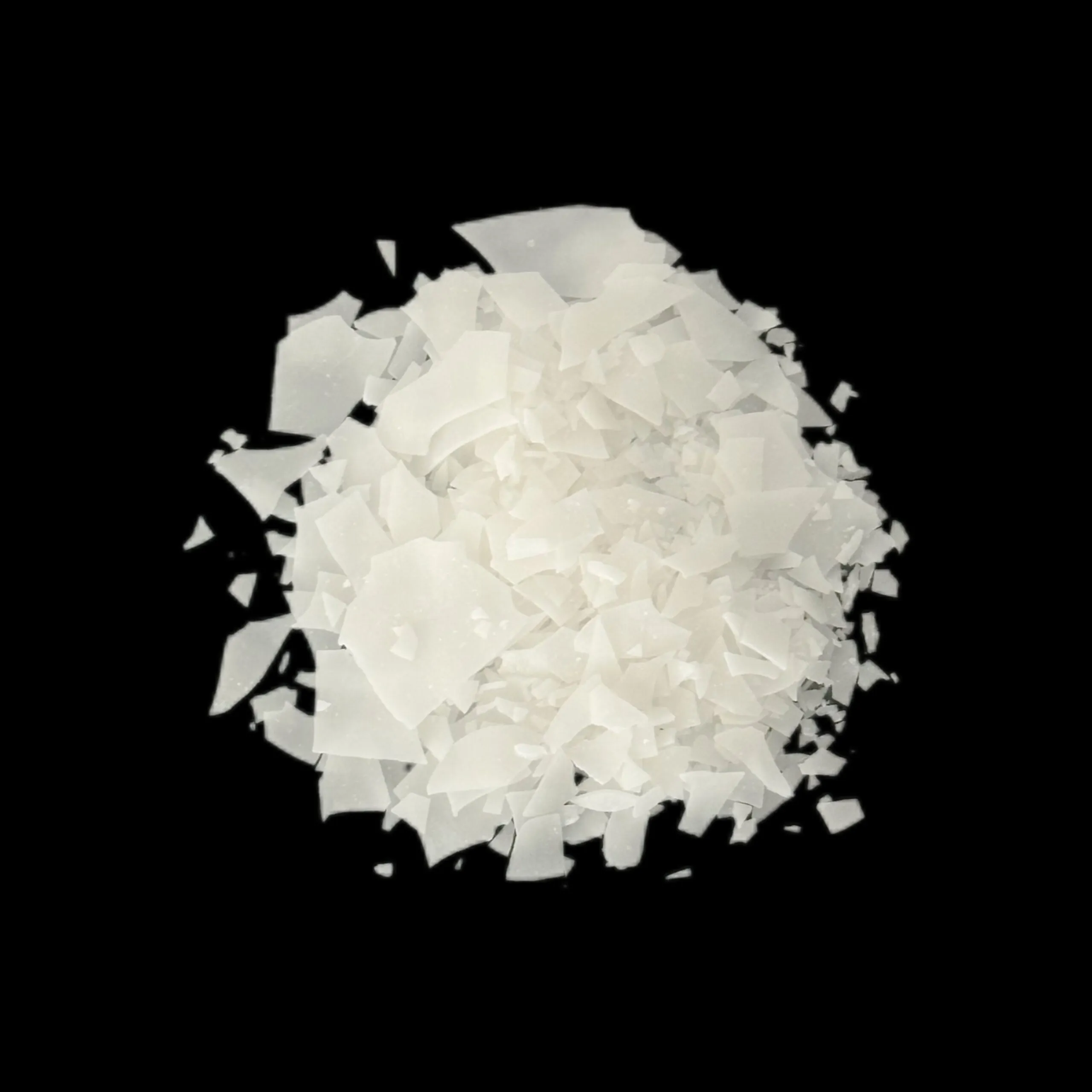

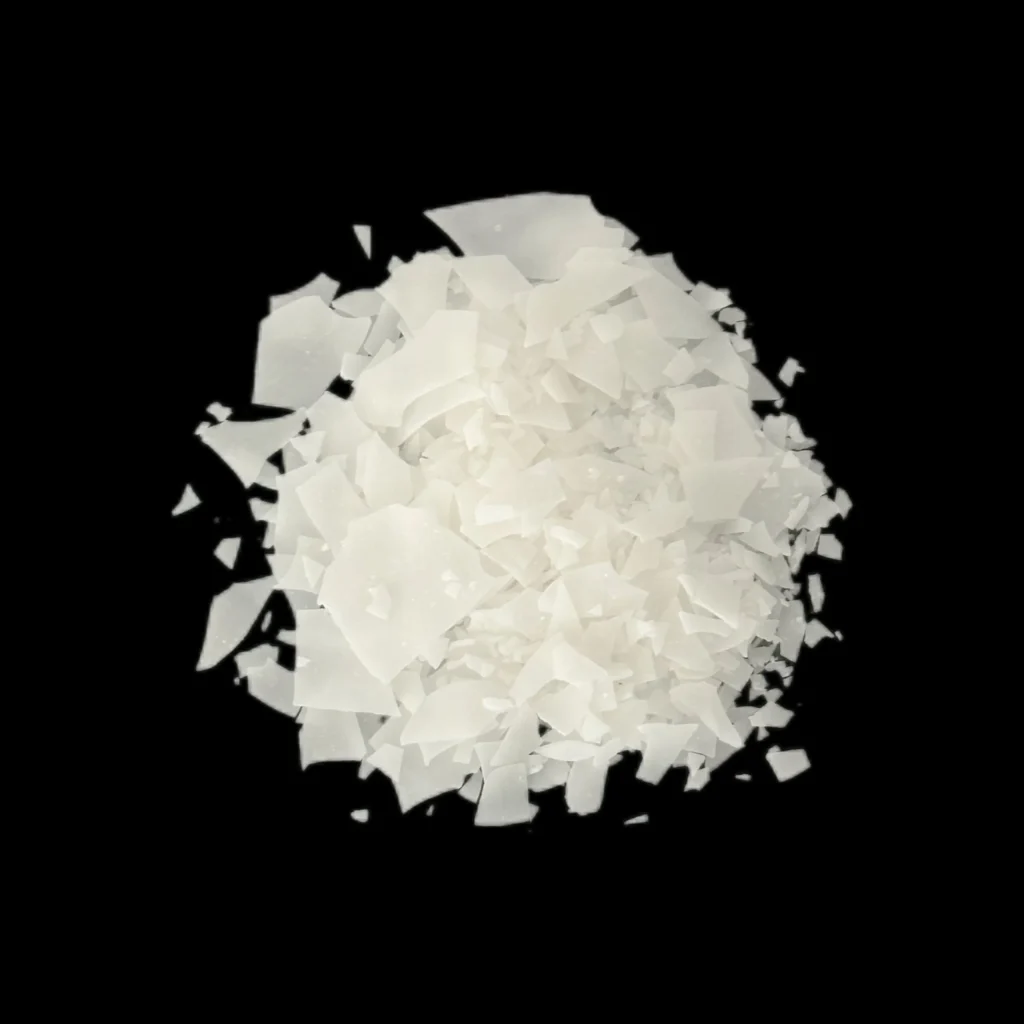

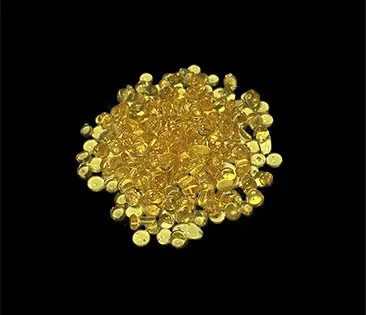

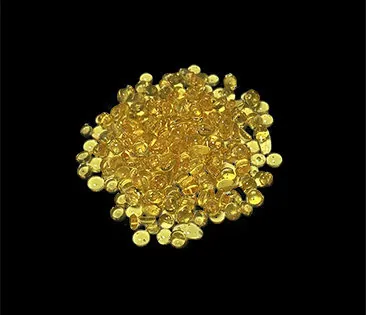

Hot melt adhesive

| Type | Color(Fe-Co) | Viscosity(Mpa.s/25℃) | Acid value(mgKOH/g) | Amine value(mgKOH/g) | Softening point ℃ | Packing |

| CXD-01 | ≤7# | 150-250 | ≤6 | ≤5 | 110±5 | 25kg two-in-one paper-plastic bag |

| CXD-02 | ≤7# | 250-350 | ≤6 | ≤5 | 120±5 |

Packaging and storage

Two-in-one paper-plastic packaging bag, 25KG/ bag.